Assembly and Application Of Mercury Slip Ring

In case you plan to enjoy enhanced performance for your heavy machineries, a mercury contact slip ring is a good choice. Mercury slip ring has advantage of enjoying performance that is same as electrical slip rings. Rather, mercury slip ring has an added advantage due to presence of the liquid metal that works on creating an enhanced conductive media. The slip ring assembly makes use of mercury as a conductive material, to transfer electrical signal under normal temperature. Additionally, it can also be kept in concern, the advantage of mercury slip ring lies in the fact that it produces lesser amount of electrical noise as compared to other slip ring assembly. Meanwhile, mercury slip ring acts as a most scientific method that allows transmission of power in the form of electrical signal to a rotating structure from a stationary structure. In simple terms of electrical engineering, a slip ring makes use of a method that initiates electrical connection by making use of rotator movements.

Mechanism behind mercury slip ring< /p>

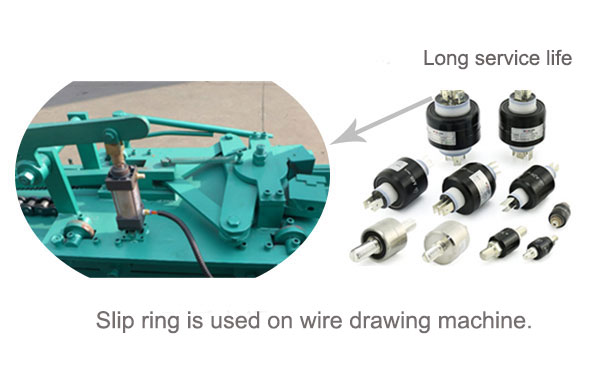

Formally, a slip ring assembly is an electric transmission device that works on allowing flow of energy between two electronic operated rotating parts, such as an electronic operatory. The advantage of mercury contact slip ring lies in the modern construction that replaces brush with pool of liquid metal. This metal has close molecular bonding thus works on maintaining between rotating and stationary contacts. The use of mercury contact slip ring is varied in industries throughout the world. Hence, a word of caution, mercury slip ring should be limited to machinery work and not used for manufacturing of food materials.

The slip ring assembly is also limited by range of temperature as mercury is known to solidify at temperature of -40 °C. That makes it a suitable choice for business operations that carry out manufacturing process in low temperature. However, the main drawback of mercury slip rings lies in the fact that it cannot be used in manufacturing process that makes use of liquid nitrogen.

Hence, it is highly recommended to opt for highly skilled individuals specializing in field of slip ring assembly and specially mercury slip ring. The traditional slip ring assembly has no match for the newly developed mercury slip ring. It should also be noted that, shock related to mechanics and vibration reduces life span.

In that regards it becomes equally important to make sure that a shock during mechanical operation is mitigated through use of shock absorbers. Sometimes it becomes increasingly difficult to understand operations related to slip rings. The limited amount of knowledge is justified due to complex working mechanism of slip rings assemblies and specially mercury slip ring.

However, this fear can be overcome with expert supervision. Hence, find your own range of required slip ring amongst the wide range and variety; make sure to choose the best one that serves your purpose of getting the most efficient work done. Associate with one of the leading manufacturers of mercury split rings in order to ensure efficacy in your machinery.

Others:

Pri: All You Need to Know About Hollow Shaft Slip Ring Next The Interdependence of Slip Ring and Thermocouple

Others:

Advantage Of A High-frequency Slip Ring

An Insight into HD Slip Ring and Virtual Reality Technology

High-frequency Slip Ring - The Ideal Modern Slip Ring

The Design Cue of Turbine Slip Rings And Its Advantages

Introduction to Slip Rings Used in Medical Field

Slip Rings In Wound Rotor Induction Motor

Rotary Electrical Connector Solving Slip Ring Dilemma for Data Equipment Manufacturer

How Does Slip Ring Induction Motor Start?

The Interdependence of Slip Ring and Thermocouple

Assembly and Application Of Mercury Slip Ring